GLP uses its licensed technology for the design, manufacture and supply of different types of cyclones for gas-liquid-solid separation for Greenfield and Retrofit projects. The cyclones are efficient in solid-liquid separation from the gas at low pressure and are perfect fit for Well Head Separators. The pressure drop across the cyclones can be as low as 10 kPa and therefore they can be used at compressor suction. The three main types of cyclones that GLP offers are:

Inlet Cyclones

Multi Cyclones

Axial Flow Cyclones

GLP has over the past 10 years supplied the above cyclones in various material including stainless steel and Super Duplex for removal of sand and water from well head gas. The cyclones are proven to be excellent replacement for the conventional coalescing filters as they do not require maintenance or repair during the normal operation and have a design life of up to 20 years.

Inlet Cyclones

Inlet Cyclones are a self-regulating, low pressure drop inlet device for high liquid load service. The primary purpose of the inlet cyclone is to eliminate foam inside a separator. Many crude oils exhibit moderate or severe foaming tendency and the traditional approach to these problems is through a combination of oversized equipment using foam breaking packs and chemicals.

Inlet cyclones work on the principle of enhanced gravity separation by accelerating any incoming foam to high g-force when it breaks down into separate liquid and gas phases.

The oil is flung to the perimeter of the cyclone tubes and flows down them into the bulk oil layer, whilst the gas forms a central vortex core and escapes through a top outlet hole into the gas space. There are many factors to consider when designing these devices so please refer to GLP Engineering for sizing confirmation.

Back to Top

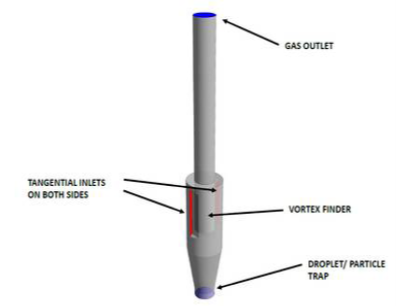

Multi Cyclones

GLP Engineering holds licensed technology for the design, fabrication and delivery of high efficiency multicyclones for efficient separation of gas/liquid and gas/liquid/solid. The multi cyclone elements feature twin, opposing inlet ports to boost the capacity of the cyclone and offer improved vortex stability. This provides a high degree of separation of liquid droplets and solid particles even at high operating pressures. The elements are positioned vertically inside the separator vessel, between two seal plates.

Our unique quick-install design means that the elements can be fitted later in the manufacturing phase, either in the workshop or at site. They are easily removed for inspection, cleaning or replacement. They can also be welded-in if preferred.

. . . . . . .

. . . . . . .

The elements have design life of over 20 years and therefore do not require any frequent replacement unlike coalescing or particulate filters.

Multi-cyclones are ideal for applications where gas flow is relatively constant, but contamination maybe either liquids and/or solids, such as may occur in long pipelines. Also they are used widely as pre-separators before cartridge filter-coalescers.

GLP Engineering’s multi-cyclone is very efficient, usually removing over 99% of contaminants above particle sizes of 8-10 microns at a pressure drop around 0.5% of the inlet pressure at design conditions.

Back to Top

Axial Flow Cyclones

GLP Engineering’s licensed design of Swirl Mist Eliminator provides a high degree of separation of fine droplets and dust even at high operating pressures. It can be positioned vertically or horizontally inside the vessel.

Due to its high capacity it is ideal for retrofitting into existing vessels when higher throughputs are required with improved efficiency. In new build applications these axial cyclones will result in significantly smaller vessels and hence give considerable weight savings and cost reductions.

The axial cyclone is extremely efficient, even at higher pressures when other mist eliminators such as vane packs lose their performance, and also when processing liquids with a low surface tension.

Typical Highspeed Axial Cyclone Deck

Back to Top